2023 Good Quality Hot dip galvanizing line - flux recycling and regenerating unit – Bonan

2023 Good Quality Hot dip galvanizing line - flux recycling and regenerating unit – Bonan Detail:

Product Description

Waste heat recovery and utilization refers to the process of recovering and utilizing the heat energy contained in gaseous (such as high-temperature flue gas), liquid (such as cooling water) and solid (such as various high-temperature steel) substances with higher ambient temperature discharged during industrial production.

The flue gas temperature of the hot dip galvanizing furnace is about 400 ℃, and a large amount of waste heat of flue gas can be recycled. Many manufacturers directly discharge this heat, causing waste of energy. Combined with heat pump technology, this part of heat can be recycled to create economic value for the factory.

Product Details

- Generally speaking, it can be used for hot water making, process heating, cooling and drying. The computer group can be configured only after understanding the waste heat and recycling the heat of the new process. When the waste heat can meet the heat energy demand of the new process, the waste heat recovery device can be directly used for heat exchange. When the waste heat cannot meet the heat energy demand of the new process, the waste heat can be used for preheating, and the insufficient heat can be supplemented by heat pump equipment, or the existing heating equipment.

In either case, the energy saving effect is much more obvious than that of the original waste heat, so as to achieve the purpose of reducing energy consumption and improving efficiency.

After the waste heat recovery from the flue gas preheating of the galvanizing line, it can be used for the hot water demand and the heating of various solutions in the pre-treatment and post-treatment processes of hot galvanizing. Customized waste heat recovery heat exchanger has high heat exchange efficiency, touch-screen operation control, and can be connected to a computer or mobile phone for easy management, saving enterprises tens of thousands to hundreds of thousands each year.

Waste heat recovery depends on heat exchanger, but system design is more important. The whole set of waste heat recovery project can only be completed if the type, temperature, and heat of the enterprise’s waste heat are well prepared in advance, and the production conditions, process flow, internal and external energy demand, etc. are investigated.

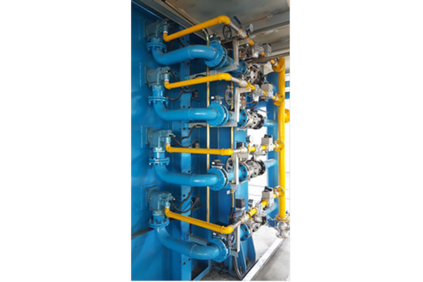

Product detail pictures:

Related Product Guide:

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs for 2023 Good Quality Hot dip galvanizing line - flux recycling and regenerating unit – Bonan , The product will supply to all over the world, such as: Holland, Ukraine, Austria, The working experience in the field has helped us forged a strong relations with customers and partners both in domestic and international market. For years, our products have been exported to more than 15 countries in the world and have been widely used by customers.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.

Write your message here and send it to us